Products

KWD industry coupling

In the course of the further development of Kupplungswerk Dresden GmbH as an innovative problem solver in the drive technology sector, and as a specialist enterprise for the production of couplings and drive components, new fields were penetrated, new sales structures were established and the company KWD Kupplungswerk Dresden GmbH was founded effective as of 1 January 1993.KWD Kupplungswerk Dresden AG is an active participant of the industrial research community within the framework of the Research Association for Power Transmission Engineering (FVA), as a result of which we promptly have the very latest findings at our disposal. In addition to modern CAD systems, state-of-the-art simulation and calculation tools (SimualtionX, Ansys) are used. Using powerful programming systems highly complex components can be prepared rapidly and through the use of high quality manufacturing technology in the shortest space of time. The linking of development, design and manufacturing enables us to flexibly respond to all market requirements. Couplings from Dresden are used in machines and installations for the extraction of raw materials, in the mechanical engineering sector, in construction and agricultural machinery, in wind power plants, in steel and rolling mill equipments and many other drives, and are rated highly due to their functionality, robustness and reliability.

Guangzhou ZEER Electromechanical Technology Co., Ltd. is the designated exclusive agent in China for German KWD industrial couplings!

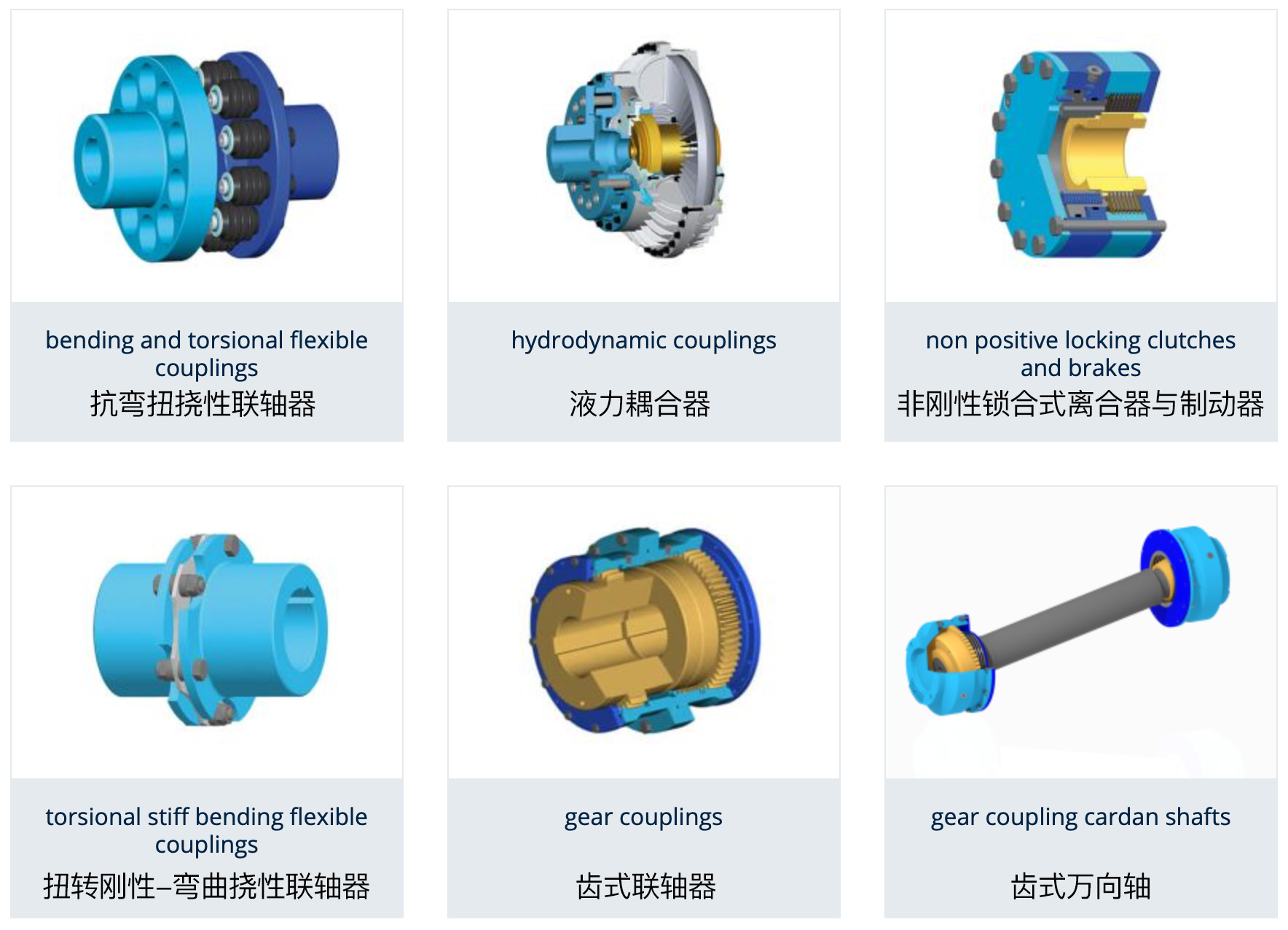

Industry couplings

1、 bending and torsional flexible couplings

1.1 flexible jaw coupling EZK

torsional and beding flexible plug in coupling

16- 2500 Nm.

1.2 flexible claw coupling ELKU, ELKU- N

torsional and bending flexibel plug in coupling in 2 or 3 parts design with brake drum, brake disc or spacer

25- 100.000 Nm.

not failsafe couplings on request

Models

1.3 flexible pin type coupling BOKU,BOKU-N

torsional and bending flexible plug in coupling with brake drum, brake disc or spacer

40 Nm - 1.000.000 Nm

Models

1.4 highly elastic couplings HEK, highly elastic clutches HESK

Highly flexible and vibration damping shaft and flange couplings

1,000 Nm - 80,000 Nm

Friction couplings HESK, DSSK, Highly elastic clutches

Switchable and vibration damping double conus friction couplings with axial, radial and angular misalignment

6,500 Nm - 160,000 Nm

Models

2、 hydrodynamic couplings

HYDRODYNAMIC COUPLING

(WITH CONSTANT FILLING) TK- N

in combination with flexible coupling, brake drum, brake disc and pulley for power up to 1750 kW

Models

3、 non positive locking clutches and brakes

3.1 multiple disc friction clutches

hydraulically and pneumatically engaged for wet and dry running

25- 150.000 Nm.

3.2 pressure released and spring operated multiple disc brakes FDLB, LB

Standard and special design

16 - 250.000 Nm

Models

3.3multiple disc safety and start up clutches LASI, LAAN

torque limiting multiple disc friction clutches for wet and dry running 25- 250.000 Nm.

Models

4、 torsional stiff bending flexible couplings

4.1 torsional stiff all steel couplings GMK

backlash free, bending flexible wear- and maintenance free couplings

200- 200.000 Nm.

4.2 Diaphragm couplings MEM

backlash free, bending flexible and torsional stiff membrane couplings for high torques at highest speeds and operation temperatures

100- 100.000 Nm.

5、 gear couplings

GEAR COUPLINGS FOR INDUSTRIAL AND RAILWAY APPLICATIONS ZAKU

for vertical and horizontal installation with large requirement for the misalignement ability, smooth running and service life.

250Nm - 1.250.000 Nm

Models

6、 gear coupling cardan shafts

The Gear Coupling Cardan Shaft with fatigue-proof gearing can replace the conventional cardan shaft in both standard and special applications.

The innovative toothing design enables an enormous power density to be transmitted even at high angular displacements and speeds, it is very durable and has virtually no wear at high torques with lower maintenance costs. Angular misalignment up to +/- 14° per joint plane possible at rated torque and speed.

250 Nm - 1.250.000 Nm